Overview

Do you have employees who can “only” take care of process optimization? Do production errors sometimes occur? Is reworking expensive here? Quality is firmly anchored in your company philosophy, but you don’t know how to improve this quality without a lot of rework? Wouldn’t it be good if someone could support you without internal blinkers?

If you answered “yes” to one of the questions, please give us a call and test us.

Troubleshooting and production monitoring

They have problems in production, but not the time to take a close look at every process and the materials used.

We offer up-to-date error analysis directly in the production process.

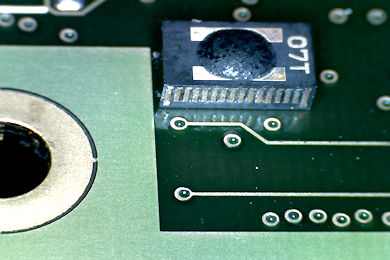

Fault analysis begins with the materials used, such as printed circuit boards, components and soldering pastes. The next examinations are the manufacturing process such as soldering paste printing, SMT assembly and the reflow process. The causes of the errors are identified and remedies are proposed.

Quality improvement

Scrap or rework has a direct impact on company profits. This also allows conclusions to be drawn about the quality. If your quality decreases and you have a lot of rework, then the defects in the materials and manufacturing processes are to be found.

We offer a quality improvement service by systematically checking the processes and materials used.

Circuit board analysis

Not sure, but the metallization is not optimal solderable? You have poor wetting of the printed circuit board?

We offer grinding and analysis of printed circuit boards.